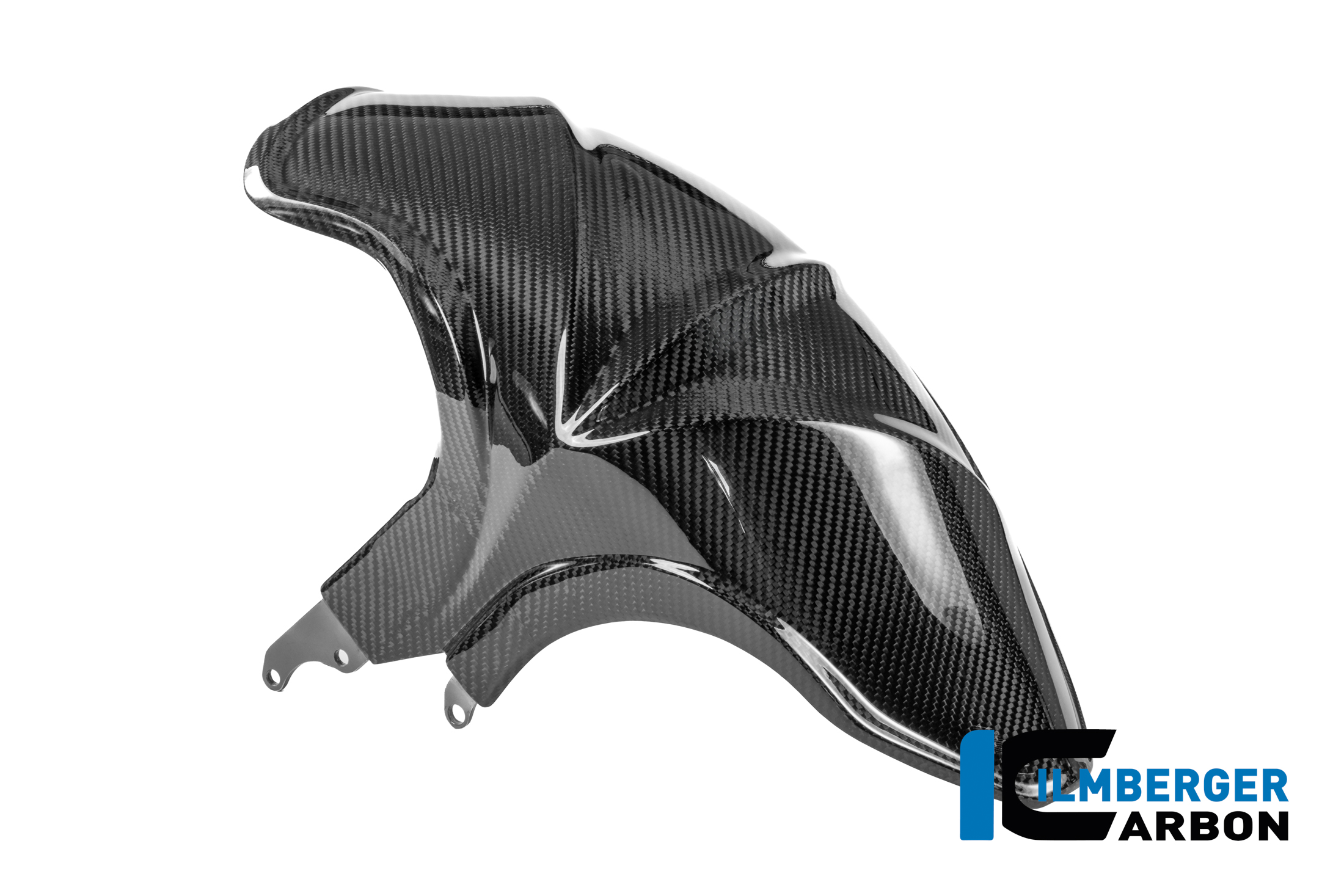

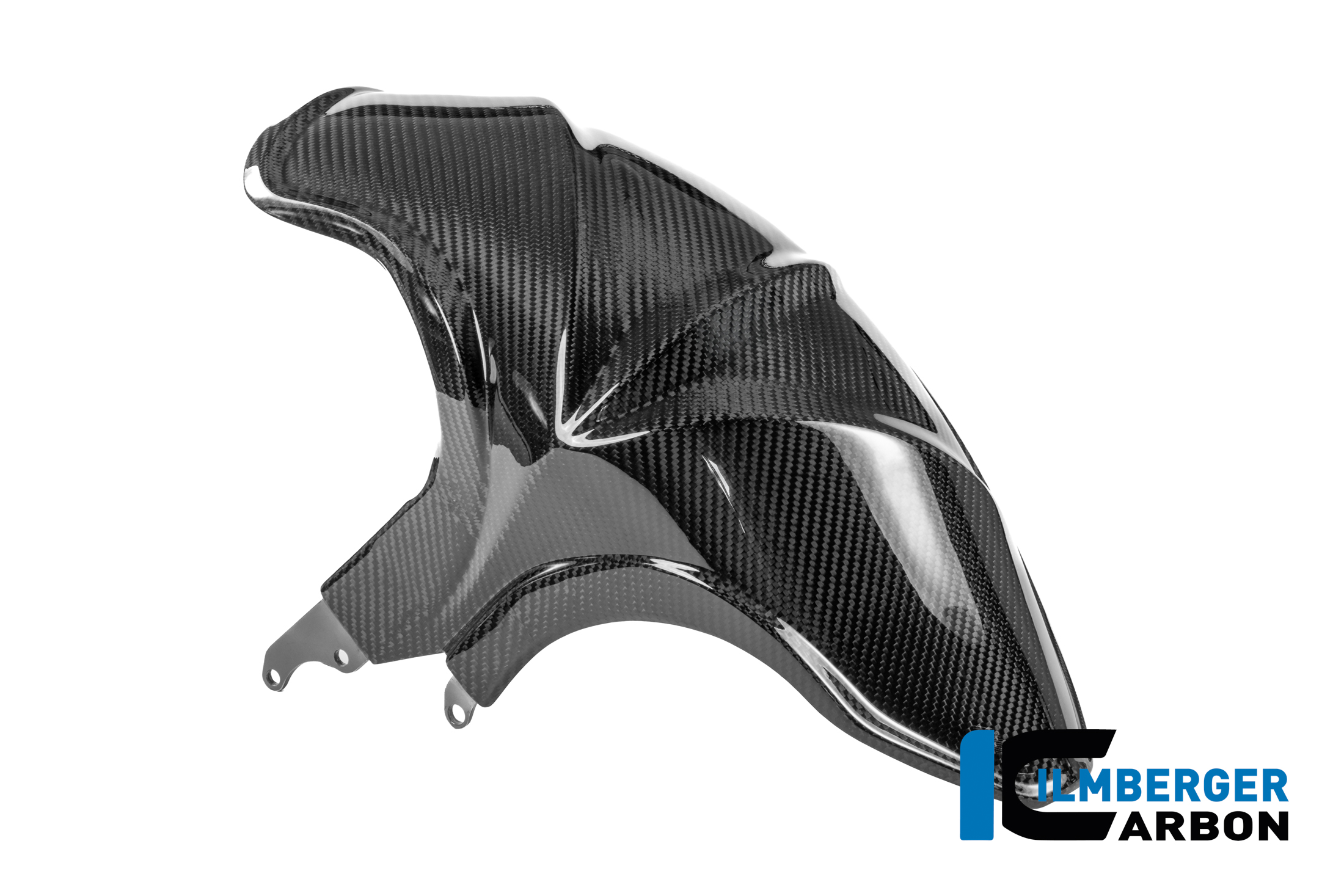

Rear fender carbon glossy BMW R 1300 R

Rear Fender for BMW R 1300 R

The rear fender for the BMW R 1300 R offers optimal protection against splashing water and dirt and blends harmoniously with the sporty design of the motorcycle. The patented fastening allows for easy installation.

Ilmberger Carbon Parts - Quality and Innovation

Ilmberger stands for the highest quality and innovation in carbon manufacturing. Each part is produced in our own production, using prepreg specifically developed for Ilmberger as the base material. This is processed in an elaborate process in the autoclave, which offers numerous advantages.

Prepreg and Autoclave Process

Prepreg is a pre-impregnated carbon fabric characterized by uniform resin distribution and a high fiber volume content. This leads to maximum strength and flexibility of the components. Processing in the autoclave ensures perfect, uniform curing and a flawless surface, free of air inclusions.

Handcraft and Precision

Our carbon parts are laminated by hand with a lot of experience and care, allowing for consistent fiber alignment without distortion. After curing in the autoclave, the edges of the parts are precisely cut by robot to ensure a perfect fit and the highest quality.

Unique Plastic Powder Coating

A worldwide unique step in Ilmberger's production is the complete plastic powder coating of all carbon parts. This protects the parts from environmental influences and gives them an incomparable depth effect. This sealing prevents the aging of the parts and significantly extends their lifespan.

Perfect Surface

The final clear coat layer is high-gloss and ensures a perfect, smooth surface that emphasizes the luxurious-sporty look of our carbon parts. Each part is a masterpiece of technology and design that meets the highest standards.

Ilmberger - Proven Expertise

Ilmberger is a leading manufacturer of carbon parts for the aftermarket and a recognized OEM producer for renowned manufacturers like Ducati and BMW. Our parts are tested under the toughest conditions in the World Superbike Championship (WSBK) and the Endurance World Championship (EWC).

Facts at a Glance

Production in our own manufacturing according to ISO Standard 9001

With ABE - no additional registration required

Use of prepreg specifically developed for Ilmberger

Manufacturing in the autoclave for maximum strength and perfect surfaces

Unique plastic powder coating for protection and a special depth effect

Lamination by hand by experts with years of experience

Precise edge cutting by robot

High-gloss clear coat layer for a flawless surface

No aging of the parts thanks to multi-layer protection against UV light

Delivery in ready-to-install condition

TÜV Certification Quality

Anyone who chooses an Ilmberger carbon part knows: The path to the finished product is demanding and requires the highest precision. An exciting insight into how Ilmberger creates each part from passion and know-how can be found in the detailed report on the production process. The in-house development is also full of innovations – discover how much dedication and technical sophistication is in every Ilmberger carbon part.