The Art of Custom Carbon Development at Ilmberger - Why True Quality Begins Before Actual Production.

Ilmberger Carbon consistently relies on independent development rather than copied solutions in the manufacture of motorcycle components. This elaborate process guarantees perfect fit, optical elegance, and technical precision – values that have distinguished the company for over 40 years.

Precision Scanning as a Foundation

Every project begins with the high-resolution 3D scan of the original motorcycle using a leading-edge Zeiss t-Scan Hawk of the 2nd generation. Up to 3,000 adhesive points per motorcycle capture every contour with millimeter precision before the relevant components are dismantled. A second scan now documents the exposed mounting points and hidden structures that are crucial for later assembly.

Once the motorcycle has been fully captured, individual components are also recorded as a reference. This first step alone often takes several days. Despite the often high time pressure, the necessary time and care must be taken here to obtain the best possible starting point for later development.

From Scan to Digital Blueprint

The resulting STL files serve as a three-dimensional spatial model, which, however, does not provide direct construction data. It is also referred to as a so-called point cloud, which is intuitively comprehensible to the human eye but hardly usable for a machine. Ilmberger engineers use this optical reference to develop each carbon part anew – a conscious decision against simply copying existing shapes. It can be imagined like three-dimensional painting by numbers, only with the difference that the components are directly altered and adjusted during tracing. In the CAD system, custom designs are created that are specifically tailored to the respective load profiles and aesthetics.

Rapid Prototyping and Fit Checks

In-house 3D printers produce prototypes that are tested on the original vehicle. This step allows for fine-tuning and brings the digital model into the real world for the first time – a decisive advantage over standard solutions. The printed model is often adjusted in parallel with the digital twin and perfected directly on the motorcycle. Only when form, functionality, and appearance harmonize perfectly does the actual tool development begin.

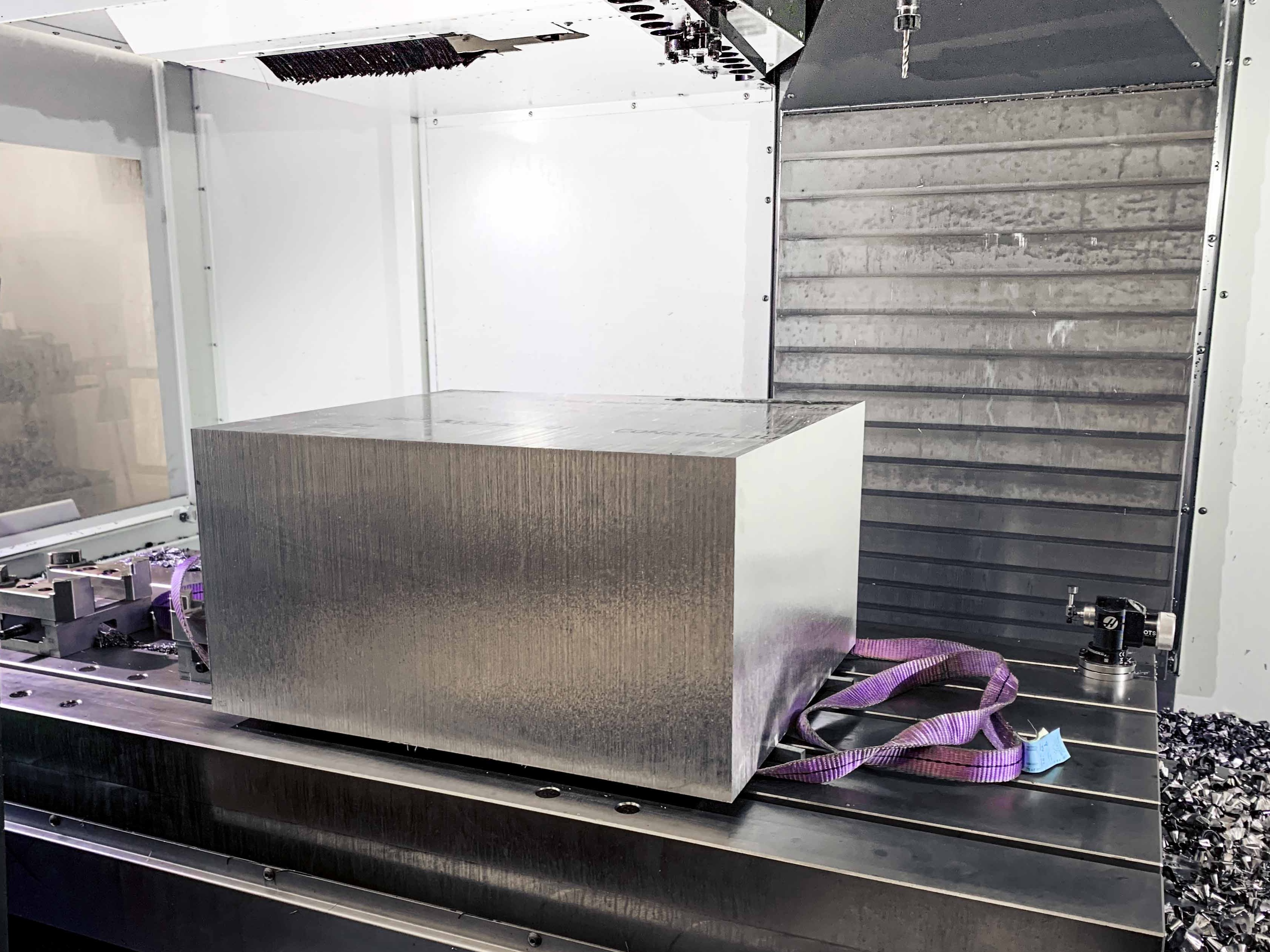

High-Precision Mold Making

The virtually optimized component data is implemented in 5-axis CNC milling machines. Close collaboration with specialized partners is involved: Each aluminum mold is created with an accuracy in the hundredth millimeter range. This precision work forms the basis for later flawless carbon parts with perfect fit.

Craftsmanship: Pattern Design

After the mold and thus the first tool have been developed, the actual model is now developed. Experienced technicians now develop the fiber layout by hand on the physical prototype. The diagonally running carbon layers are positioned with millimeter precision before digitized patterns later control the plotter. This interplay of craftsmanship and digital technology ensures the characteristic Ilmberger look with maximum material efficiency.

The Often Forgotten Additional Tools

The mounts on the motorcycles are becoming increasingly complicated. Where simple screws were used a few years ago, plugs and hooks are used today. This allows for visually appealing assembly with hardly visible mounting points, but greatly increases the complexity of a carbon part. Many of the required brackets cannot be directly laminated in carbon but must be glued as separate holders into the carbon part. In the first master model, this is done by hand, the adjustment is made directly on the motorcycle and double-checked with the scanner. Based on this master model, also known as the master sample, tools and mounts for gluing are now manufactured. In later production, the carbon parts and the holders can be glued together precisely.

Quality Assurance at the Highest Level

After the parts and tools have been developed, the components must be tested in practice. Ilmberger Carbon relies on a multi-stage, practice-oriented testing process for quality assurance of its carbon parts. Each new component is first tested by experienced employees on closed grounds or directly on the racetrack under the toughest conditions. These tests under real conditions ensure that fit, functionality, and durability meet Ilmberger's high standards. Only when a carbon part passes these intensive tests does the next step begin: certification by independent testing institutes.

A central element of quality assurance is cooperation with TÜV. Ilmberger Carbon was the first manufacturer to receive an ABE (General Operating Permit) and TÜV certification for carbon parts for the German market. For approval, the components are tested according to strict criteria for safety, stability, and workmanship. TÜV checks the proper installation on the vehicle, documents the assembly with photos, and examines all safety-relevant aspects. Only when all requirements are met is an ABE issued. This allows the part to be used without additional entry in the vehicle documents – the report only needs to be carried along. The gold standard in the approval of components for road traffic.

Parallel to the technical examination, Ilmberger produces all necessary documents such as installation instructions. These are designed to enable simple, comprehensible installation – without any special tools. This ensures that even less experienced mechanics can easily install the high-quality carbon parts.

Benchmark for Innovation, Aesthetics, and Durability

Ilmberger Carbon has always stood for innovation and sets standards in the development and production of carbon parts for motorcycles. The company consciously takes the elaborate path of independent development to achieve not only a perfect fit and exceptional aesthetics but also to maximize the lifespan of its products. Each part is designed to withstand the stresses of everyday life and the challenges on the racetrack equally. The special production in the autoclave, the high-quality plastic coating, and the precise processing ensure exceptional robustness and protection against environmental influences.

Another central concern of Ilmberger is the easy installation of the carbon parts. The constructions are designed to be mounted at the original attachment points – usually without any special tools. This not only allows for quick and uncomplicated retrofitting but also guarantees that the parts can be removed at any time without leaving any residue.

Ilmberger Carbon thus remains a pioneer in the industry: With uncompromising development work, uncompromising quality, and a clear focus on durability, aesthetics, and user-friendliness, the company sets standards by which others must measure themselves.

Through complete control over every development and production step, carbon parts are created that set new standards in form, function, and durability – made by Ilmberger, for motorcycle enthusiasts who accept no compromises.