My Life as a Carbon Part: My Creation Story at Ilmberger

I am a carbon part, and today I will take you on my journey through production at Ilmberger Carbon. I will show you how an inconspicuous roll of prepreg carbon becomes a finished carbon part.

My Origin: From Prepreg Blank to Custom Cut

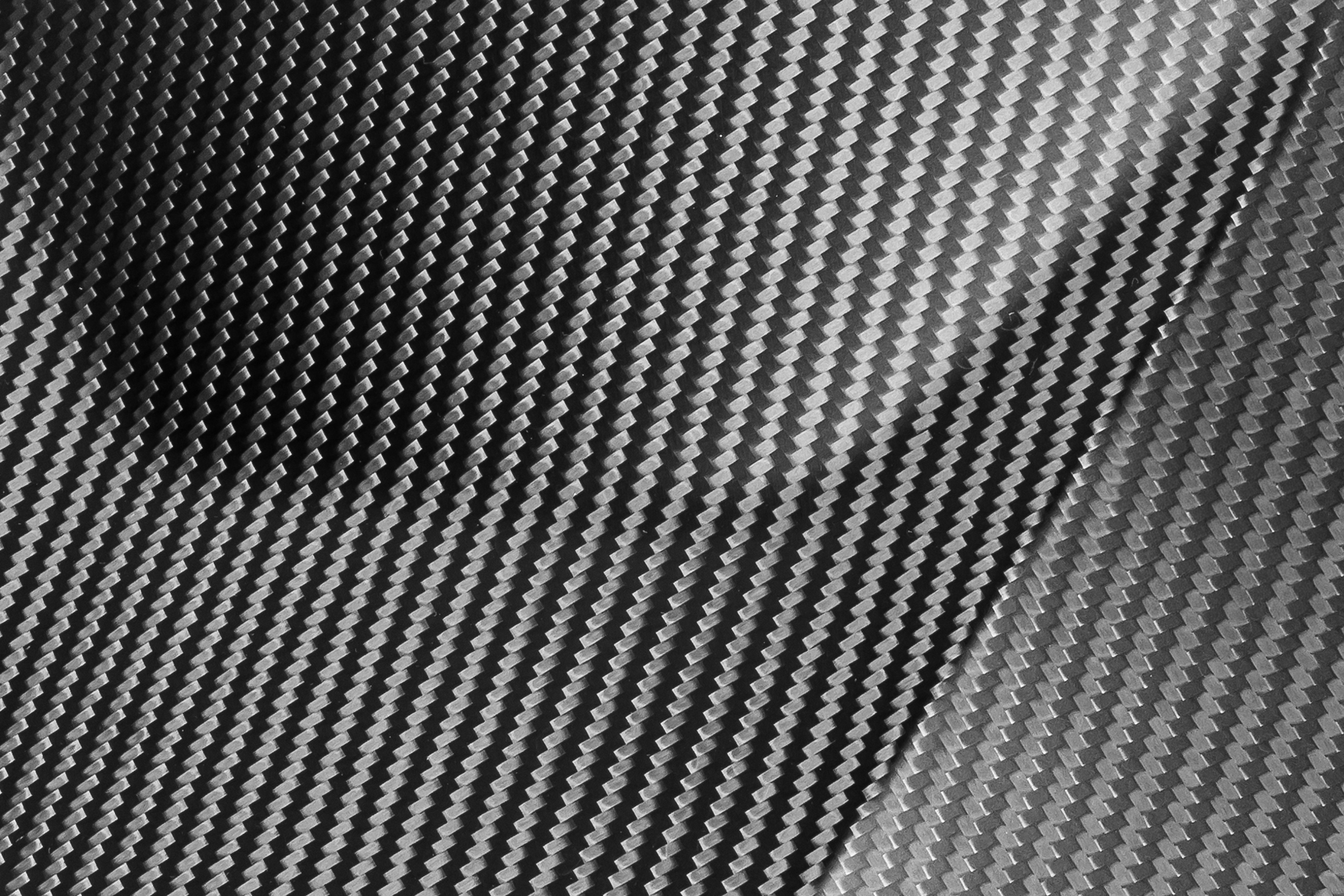

Everything begins with me as an inconspicuous piece of prepreg carbon. What makes me special: My fibers are already pre-impregnated with resin. This ensures that only the necessary amount of resin is in the fiber fabric and that it is evenly distributed. You can think of carbon like this: Carbon always consists of two components, hence the name composite material. One component is the fabric, which consists of thousands and more individual carbon fibers, which are first woven into strands and later into mats. The weave type and the strength of the individual strands can be varied, which is important for the later appearance and strength of the material.

These mats are still very flexible, almost like a strong sweater or a thin jacket, but very stable in the tensile direction of the individual fibers. Carbon fibers are among the strongest and lightest, but also the most expensive fiber types compared to fiberglass or Kevlar. Therefore, they are always preferred when parts are mechanically stressed and weight is crucial, as is the case in Formula 1 or MotoGP. These fibers now need to be bonded with a resin, which enables a later three-dimensional shape.

There are various resins, depending on the application and requirements. For example, a tank needs a resin that is impermeable and chemically resistant, while an exhaust heat shield or engine spoiler requires a resin that can withstand significantly higher temperatures. Since resin is comparatively heavy and begins to take mechanical load away from the much more stable fibers at too large a volume, a rule of thumb is that the optimal amount of resin is as much as necessary but as little as possible. Achieving this optimum consistently in production is one of the most challenging aspects and crucial for the later quality of the components.

Ilmberger takes many steps to make this possible. As raw material, only prepreg is used, where the resin is applied directly by a specialist in Italy in a dipping tank and with a roller evenly and then pressed out in several steps.

Ongoing analyses and controls in the in-house laboratory there ensure consistent quality. A special transport and storage strategy to the production plant in Bosnia ensures that the material behaves consistently throughout the year, so that seasonal fluctuations due to temperature and humidity can be compensated.

This prepreg serves as the basis for me. So that I can later be laminated in several layers, so-called patches are first cut from the respective correct raw material. These cutting patterns allow for less waste during lamination and provide a clear direction for the diagonal of the material, as we will see, another important aspect for both stability and appearance on the finished motorcycle. Cutting the patches is done by a state-of-the-art Zünd plotter, which works fully automatically and cuts me with the highest precision into the shape I will later have as a component.

.jpg)

A sophisticated nesting algorithm ensures that as little material as possible is wasted and my fibers always lie at the same angle. For each component, several layers of patches are cut, which can then be laminated in different diagonal directions. A small but very important detail for later stability, as one layer can only be stable in two directions, each offset by 90°.

From Flat Fabric to Complex 3D Shape: Laminating with a Delicate Touch

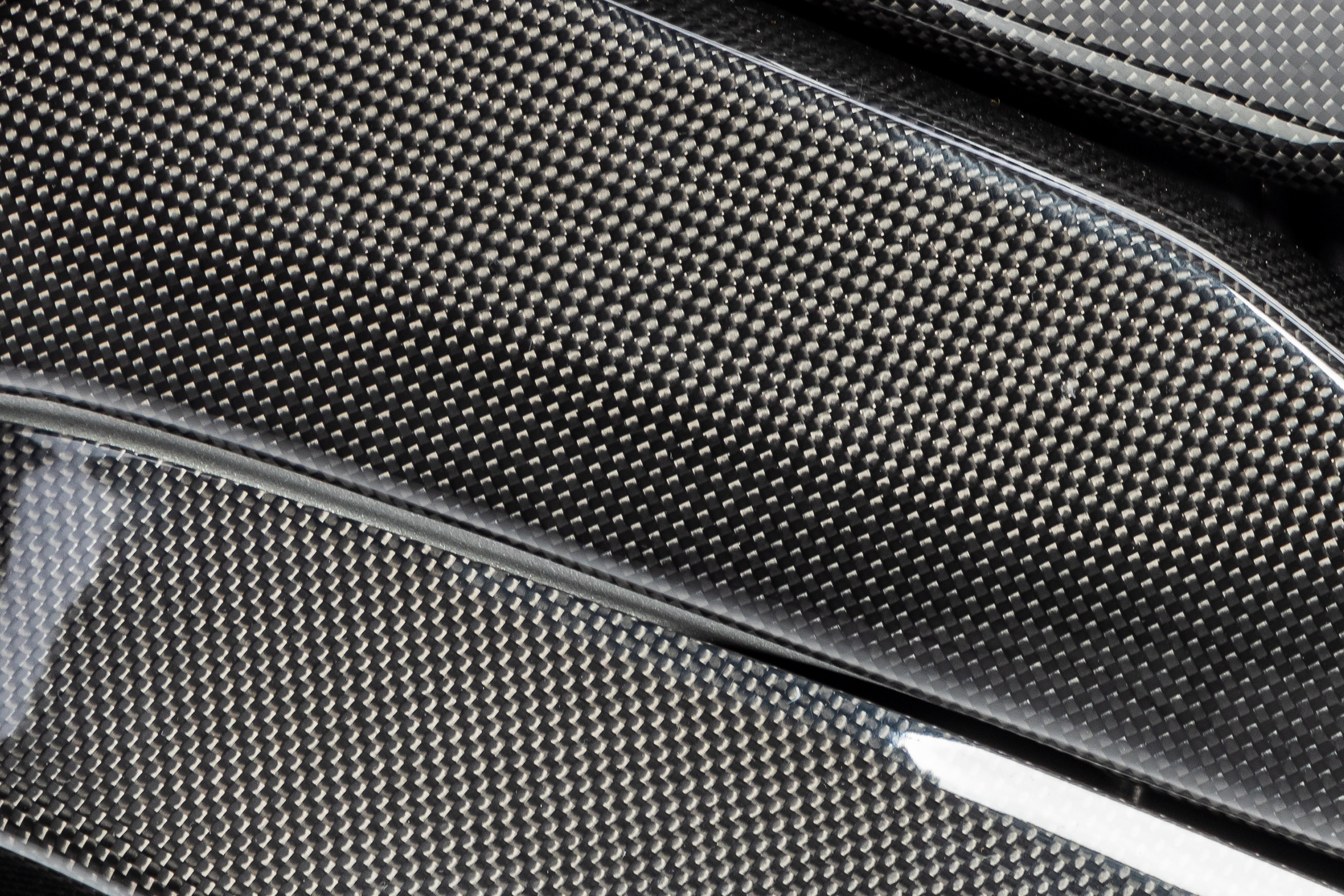

After I have been cut, it's time for laminating. A step where real hands are still involved, making each part a handcrafted work. Without a doubt, I can say that this is probably the most elaborate and craft-intensive step of my journey. Several layers of me are placed by experienced hands into a CNC-milled aluminum negative mold. The experts ensure that my individual layers are precisely positioned and local reinforcements are incorporated – this gives me the perfect balance between stability and lightness. The challenge: turning my two-dimensional fabric into a three-dimensional shape. Every corner, every curve must be adjusted so that I do not bulge or warp.

.jpg)

Anyone who has ever tried to apply a film has an idea of what this means. My prepreg mats cannot be stretched or heated with a hairdryer, as this would be immediately visible in the later structure of the finished part. The different mats also stick to each other immediately, as the resin is sticky at room temperature. For large and complex parts like an engine spoiler, laminating usually takes several hours. The workplace is subject to strict regulations to ensure that no dust particles can nest between my fibers.

Vacuum Fun: Under Pressure in the Bag

Now it gets exciting: I am packed along with the mold in a special plastic bag with a vacuum valve. A vacuum sucks me tightly into the mold and removes even the smallest air inclusions. This is extremely important for my later mechanical properties, as only this way will I be particularly stable and flawless. Additionally, I do not shift a millimeter during further handling – everything remains exactly in place.

Heat Treatment in the Autoclave: My Curing Under Extreme Conditions

Now the autoclave awaits me – a pressure oven where I cure at high temperature and under pressure. During this process, an absorbent fleece, which is in the vacuum bag with me, ensures that excess resin is pressed out and absorbed. This further increases stability and reduces my weight. A real sweat cure. After curing, I am carefully removed from the mold.

.jpg)

Especially with components with complex undercuts, this is a real challenge, as I love to stick in the mold but must not get a crack.

First Quality Control: Only the Best Move On

Now that you can finally see what I want to become, the first rigorous examination begins. I am already thoroughly inspected: Am I correctly cured? Are all layers flawlessly laminated? Are there air inclusions or other defects? If so, I unfortunately have to be sorted out – only the best parts make it to the next round.

Precise Cutting: The Robot Takes Over

Now high-tech comes into play: A robotic arm cuts my edges and future holes with the highest precision. It feels like being at the dentist. But this way, we always look the same, and I am ready for the next steps. I could already be released into the wild, which unfortunately often happens. But unprotected from sun and weather, my life would be short and painful... The UV light would damage the resin, and I would yellow and my surface would quickly become brittle. Within a short time, I would age rapidly and become weak. But fortunately, there are ways to keep me stable and fresh.

Preparation for Assembly: Mounts and Clips for a Perfect Fit

But before I am protected, my inner sides get mounts and clips glued on. These ensure that I can later be perfectly mounted on the motorcycle. Specially made adhesive jigs guarantee the highest precision and fit of all clips so that we all fit equally well on your motorcycle.

Exclusive at Ilmberger: The Plastic Powder Coating - The Time Capsule of Carbon Production

Now follows a step that makes me immortal: I receive a plastic powder coating on all sides, edges, and holes. This layer is thicker and more resistant than conventional clear lacquer and optimally protects me from environmental influences, UV light, and mechanical stress. At the same time, it enhances the optical depth effect of my carbon structure and ensures that I practically no longer age. A small step in production, but a gigantic leap in the quality of the parts. This step is technically not easy and has taken years to be applied in series.

At the same time, you can recognize me and other Ilmberger parts by our smooth inner surface. In almost all carbon parts, the inner side remains raw, you can feel it directly with your finger, it almost feels like sandpaper. My surface is also smooth on the inside, a difference you can feel. Since the powder is white when applied, we are also quite sure that no spot is accidentally overlooked. Only when I am snow white is the powder baked in and my surface sealed.

.jpg)

The Finale: The Clear Coat for Perfect Shine or Noble Matte

Now I am coated with clear lacquer – glossy or satin matte, depending on the wish. This step is purely aesthetic and makes me shine particularly. The powder coating as a primer ensures that my surface becomes particularly smooth and sleek. If the clear lacquer were applied directly to my raw surface, it would lead to problems with unsightly solutions. The lacquer would run into the pores of my raw surface, resulting in an unsightly orange peel. Many manufacturers solve the problem with multiple and increasingly thicker layers of lacquer, but with that, I lose my lightweight and become heavy. Also, a clear lacquer is never 100% transparent, so my beautiful carbon structure becomes increasingly cloudy with increasing layer thickness. This is especially noticeable in the sun, where I then look almost a bit milky. Like when you apply too much sunscreen to your skin. Fortunately, this problem was solved at Ilmberger with the plastic coating at the root, so I remain light and crystal clear even in the strongest sun.

My matte lacquered colleagues are painted in the same matte as the original Ducati parts. This allows you to perfectly combine them with Ducati OEM and Ducati Performance parts. Since the original parts are also cut on the same plotter, we are quite sure that the diagonals and our Ilmberger parts seamlessly integrate into the original carbon parts.

However, I am a glossy carbon part, so in the last step, I am polished by hand again. You could also say I receive the final touch for an absolutely perfect appearance.

One Last Check: Only Perfection Leaves Ilmberger

After I have taken this long and arduous path, I undergo a thorough final inspection once again. Every detail is checked: surface, fit, stability, and appearance. Only if I am flawless in all aspects am I allowed to leave the production facility and look forward to my new life on the motorcycle – ready to meet the highest demands.